I have added a router to my homemade CNC machine. It used to smoke at a feed rate over 20% with the Dremel. Now with the router it can cut at 100% and the cuts are much smoother.

It can also cut right through the board. I changed the feed rate while the Z axis was moving and caused it to crash, almost cutting through the board. That is visible in the bottom left side of the "N".

Here is the video, it was taken after the crash.

http://youtu.be/k2YVhZnzZ2k

I am also upgrading it to an aluminum frame, this makes the machine more solid than Plexiglas.

This CNC machine can be built with my plans found in my latest book "inexpensive CNC Projects".

Tuesday, July 29, 2014

Monday, July 21, 2014

My latest book "Inexpensive CNC Projects" and a trip to Florida

I just returned from a quick trip to Florida. I drove for over 3,000 miles in only eight days! I went to visit my dad and to give him a copy of my latest book "Inexpensive CNC Projects". It is dedicated to him because he was a CNC programmer at Ingersol Rand for many years.

Here is a picture of me giving him the book at the nursing home.

We also stopped at the creation museum on the way home. I was studying the skeletons of the dinosaurs and how they were animated to get ideas for making my next project - a life sized robo raptor!

Here I am next to an animated raptor.

Here is a picture of a raptor skeleton.

Here is a picture of me giving him the book at the nursing home.

We also stopped at the creation museum on the way home. I was studying the skeletons of the dinosaurs and how they were animated to get ideas for making my next project - a life sized robo raptor!

Here I am next to an animated raptor.

Here is a picture of a raptor skeleton.

Monday, June 23, 2014

One Crazy Virus claimed to be from the "Metropolitan British Police"

Someone showed me a computer this weekend with a virus that I could not even beat in safe mode. All I could do was to re-install Windows. The best I could do was to get the task bar to pop up for a split second. In safe mode the computer just restarts into regular mode and went back to this screen.

I had to use a camera to take a picture of it.

Another problem is that Malwayre-Bytes anti Malware (MBAM) no longer offers a thorough search and even once I re-installed windows it did not detect the virus as it was in "Old Windows". Then there is Microsoft security essentials that will not do a scan unless you are connected to the Internet to do an update.....

I had to use a camera to take a picture of it.

Another problem is that Malwayre-Bytes anti Malware (MBAM) no longer offers a thorough search and even once I re-installed windows it did not detect the virus as it was in "Old Windows". Then there is Microsoft security essentials that will not do a scan unless you are connected to the Internet to do an update.....

Monday, June 16, 2014

2014 Chafee NY Hamfest

The Chaffee NY Hamfest was a little bigger than last year. It is still one of the smallest ones that I go to. Here are some pictures that I took.

Here is my table. It was so cold that I never used that chair. Note the bin of 5 inch RF cavities. I was selling it for a friend but did not get any offers.

Note that their were vendors on both sides of the "road".

There was some spare room under th roofs but it was not raining.

Here is my table. It was so cold that I never used that chair. Note the bin of 5 inch RF cavities. I was selling it for a friend but did not get any offers.

Note that their were vendors on both sides of the "road".

There was some spare room under th roofs but it was not raining.

Wednesday, May 21, 2014

Element FLX-2211B 22 inch LCD TV Repair

My daughters LCD TV recently died. She said that it would have to warm up for a while before it would turn on and then finally it did not turn on at all. I told her that the power supply needed new caps and proceeded to take it to my shop to fix it.

The first problem was how to get it apart. There is a hidden screw that you have to remove first. Remove the lower part of the base to get to it. Then to the left of where the base attaches there is a screw up in there to remove as seen in this picture. Then the rest of the base comes off.

The power supply only needed two capacitors, they are marked with red arrows, but you can replace a few more capacitors if you want "just in case."

Here is the back cover of the LCD TV for identification purposes.

The first problem was how to get it apart. There is a hidden screw that you have to remove first. Remove the lower part of the base to get to it. Then to the left of where the base attaches there is a screw up in there to remove as seen in this picture. Then the rest of the base comes off.

The power supply only needed two capacitors, they are marked with red arrows, but you can replace a few more capacitors if you want "just in case."

Here is the back cover of the LCD TV for identification purposes.

Friday, May 16, 2014

Homemade DIY CNC Pendant to test out CNC equipment

Last night I finished building my DIY CNC pendant and tested it out. I still need to add a manual jogger to it someday. It is made out of an old Zenith TV remote control. The key is to have three position toggle switches. I have a lot of them laying around that were left over from another project. You can build this for about $25 or for free in my case because I used parts that I had laying around. It will be in my next book "Arduino CNC Projects".

Here is what the insides of the CNC Pendant look like. The 555 is on the left side and the 9 volt battery is only safe to use if all of your CNC inputs have opti-couplers. The cable is a 4 pair network cable.

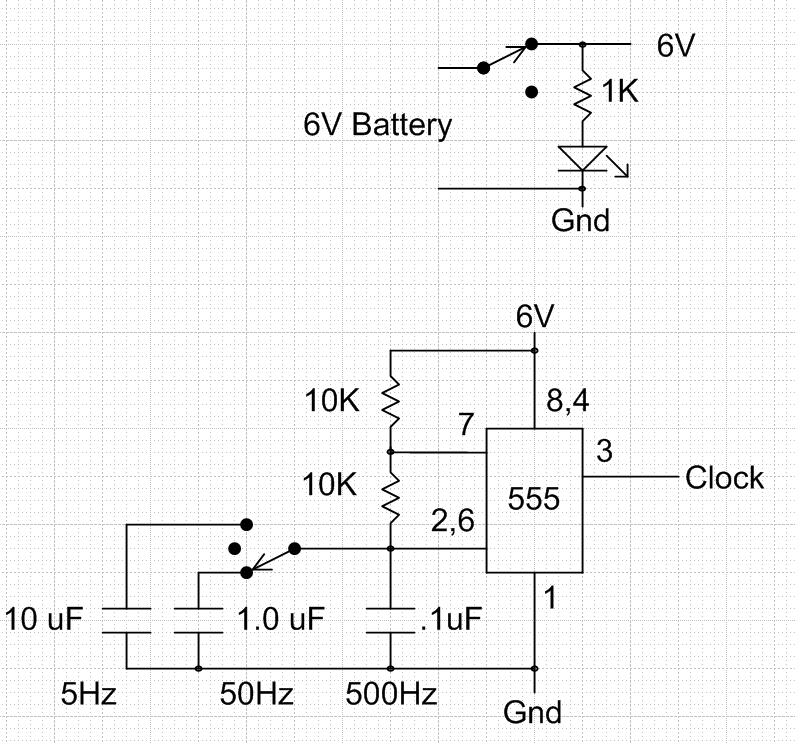

This is the schematic diagram of the wiring of the direction switches. You need either 6 Volts or you can use 9 volts and a 5 volt regulator.

This is the wiring of the 555 timer and the power switch. Either use 6 volts or add a 5 volt regulator to protect your BOB (Break out Board) from the excessive voltages. I was using an old battery that was only putting out about 6 volts. You might also be able to tap into 5 volts from your CNC.

Here is a link to a video of the homemade CNC and this pendant working. This video was from before the 555 was put inside of the pendant. http://youtu.be/nbSun9bJMPo

Here is what the DIY CNC looks like today.

Here is the latest video on YouTube: http://youtu.be/YB4Aem0amOo

Here is what the insides of the CNC Pendant look like. The 555 is on the left side and the 9 volt battery is only safe to use if all of your CNC inputs have opti-couplers. The cable is a 4 pair network cable.

This is the schematic diagram of the wiring of the direction switches. You need either 6 Volts or you can use 9 volts and a 5 volt regulator.

This is the wiring of the 555 timer and the power switch. Either use 6 volts or add a 5 volt regulator to protect your BOB (Break out Board) from the excessive voltages. I was using an old battery that was only putting out about 6 volts. You might also be able to tap into 5 volts from your CNC.

Here is what the DIY CNC looks like today.

Here is the latest video on YouTube: http://youtu.be/YB4Aem0amOo

Wednesday, April 30, 2014

DIY Raised Gardens in NY with very little land

Last year I started a small raised garden. I started the plants indoors in March and then moved them outdoors into two raised beds made out of 2 by 6's. Each one was about 8 feet by 3 feet in size.

Last year I used egg cartons to start the plants, they were way too small! This year I used mostly yogurt containers to start my plants. The plants seem to thrive in these yogurt containers. I poked a hole in the bottom of them to help prevent over-watering. I also bought some plant starter kits. They were a total flop, only about 8 out of 36 plants grew! All of the seeds in the yogurt containers grew. The problem with the starter trays is that the "dirt" must be pointed up before the water is added. Otherwise the dirt expands crosswise and is under too much pressure for the plants to grow. Also the potting soil that was used in the yogurt containers is far more effective in starting plants.

Here is a picture of them after about a month. The cardboard type of seed starters are better than the yogurt containers in the long run. They are ready to go in the ground, half of them are already planted.

Here is what my garden looked like last year when everything was first planted outside. The peas are in the front row.

This is an update - the garden in June.

This is what the garden looked like at the end of last summer. The peas have died and cucumber and zucchini have taken over.

Another secret to gardening is to use rain water. I have a large plastic trash can that fills with rain water to keep the garden watered. If you must use tap water then let it sit overnight first.

Last year I used egg cartons to start the plants, they were way too small! This year I used mostly yogurt containers to start my plants. The plants seem to thrive in these yogurt containers. I poked a hole in the bottom of them to help prevent over-watering. I also bought some plant starter kits. They were a total flop, only about 8 out of 36 plants grew! All of the seeds in the yogurt containers grew. The problem with the starter trays is that the "dirt" must be pointed up before the water is added. Otherwise the dirt expands crosswise and is under too much pressure for the plants to grow. Also the potting soil that was used in the yogurt containers is far more effective in starting plants.

Here is a picture of them after about a month. The cardboard type of seed starters are better than the yogurt containers in the long run. They are ready to go in the ground, half of them are already planted.

Here is what my garden looked like last year when everything was first planted outside. The peas are in the front row.

This is an update - the garden in June.

This is what the garden looked like at the end of last summer. The peas have died and cucumber and zucchini have taken over.

Another secret to gardening is to use rain water. I have a large plastic trash can that fills with rain water to keep the garden watered. If you must use tap water then let it sit overnight first.

Tuesday, April 15, 2014

DIY Arduino CNC Projects for 3D printing, engraving, etc.

I am working on making my own Arduino powered CNC 3D printer and light duty milling machine. It started off as just some pieces of Plexiglas and parts salvaged from some old scanners and printers. I will likely write my next book about building your own "Arduino CNC Projects".

I added some wood for the main platform and used an old LED sign board to hold the electronics. The Robo raptor is jealous that I am no longer playing with him.

I bought a ball screw drive for the Z axis on eBay and figured out how to mount it. The X and Y axis were belt driven but kept binding up and had too much play in them.

Next I upgraded to NEMA 23 stepper motors and ball screw drives for the X and Y axis. Now it runs much smoother.

The mechanical part is just about done, but the electronics will need a lot of work before it starts running. Currently the Arduino is driving the steppers through some L298 driver IC's.

Here is the electrical so far. I have built a L297 interface board but it is still not working properly.

I added some wood for the main platform and used an old LED sign board to hold the electronics. The Robo raptor is jealous that I am no longer playing with him.

I bought a ball screw drive for the Z axis on eBay and figured out how to mount it. The X and Y axis were belt driven but kept binding up and had too much play in them.

Next I upgraded to NEMA 23 stepper motors and ball screw drives for the X and Y axis. Now it runs much smoother.

The mechanical part is just about done, but the electronics will need a lot of work before it starts running. Currently the Arduino is driving the steppers through some L298 driver IC's.

Here is the electrical so far. I have built a L297 interface board but it is still not working properly.

Here is a link to the video on youtube: https://www.youtube.com/watch?v=RL-55GaYAvs

Wednesday, April 9, 2014

Projectors for Africa Part 2

Years ago I was in Africa with my brother. We were setting up a video Bible school and we purchased a large TV to show the video's on. However the guy using the TV only had a bicycle to haul it around with. I thought "If only I could send over some Projectors!" That year we started sending video projectors to Africa.

Last year I refurbished over 20 Video projectors for use in Africa and in the Philippines. This year I have already purchased over a dozen used projectors that need to be refurbished. That included cleaning and adding a new air filter.

My brother just took a load of projectors over to Africa and sent back these pictures of happy pastors. He includes a Video Bible School and some of his teaching Video's.

We need DVD players, power cables, VGA cables and A/V cables. If you have any you want to donate let me know.

Last year I refurbished over 20 Video projectors for use in Africa and in the Philippines. This year I have already purchased over a dozen used projectors that need to be refurbished. That included cleaning and adding a new air filter.

My brother just took a load of projectors over to Africa and sent back these pictures of happy pastors. He includes a Video Bible School and some of his teaching Video's.

We need DVD players, power cables, VGA cables and A/V cables. If you have any you want to donate let me know.

RAWNY Mini Hamfest in Tonawanda NY

Last night I attended the RAWNY mini Hamfest in Tonawanda NY. It was actually fairly well attended and I got rid of at least 3 boxes of stuff as well as sold about 5 or 6 books.

Here is a picture showing the awarding of the prizes.

Here is my table. Someone said that i had the cleanest table there. I had all my free junk hidden underneath it!

I might have brought home almost as much stuff as I took. I collected several 12 volt 5 amp AC adapters for free. I purchased many VGA cables for $3 each. I even picked up something that I did not know what it was. I think it might be a serial port RS-232 to Coax converter.

Here is a picture showing the awarding of the prizes.

Here is my table. Someone said that i had the cleanest table there. I had all my free junk hidden underneath it!

I might have brought home almost as much stuff as I took. I collected several 12 volt 5 amp AC adapters for free. I purchased many VGA cables for $3 each. I even picked up something that I did not know what it was. I think it might be a serial port RS-232 to Coax converter.

Friday, January 31, 2014

Arduino powered Roomba Robot

I have taken a iRobot Roomba vacuum cleaner apart and made an Arduino Powered robot out of it. There is a serial port on the Roomba, but mine was dead so I wanted to do a complete rebuild. I am using a L298 motor controller IC. The Arduino is on the back right corner in the picture below.

At first I was just interested in how much power the Roomba has. It easily got around with about 20 pounds of added weight and could push chairs out of its way. My long term goal is to make a life sized robo-raptor and this would make a nice foot. I have videos of a 2 foot long robo-raptor also under control of an Arduino.

Here are the videos:

http://www.youtube.com/watch?v=6Kd9IM1UDb8

http://www.youtube.com/watch?v=f9-WJ3wGICo

At first I was just interested in how much power the Roomba has. It easily got around with about 20 pounds of added weight and could push chairs out of its way. My long term goal is to make a life sized robo-raptor and this would make a nice foot. I have videos of a 2 foot long robo-raptor also under control of an Arduino.

Here are the videos:

http://www.youtube.com/watch?v=6Kd9IM1UDb8

http://www.youtube.com/watch?v=f9-WJ3wGICo

Thursday, January 9, 2014

Arduino powered Robo-Raptor

I have been working on rebuilding a Robo Raptor to be controlled by an Arduino. It is a key project in my latest book "Arduino Robotics Projects" available on Amazon.

Here is a link to the video on YouTube:

http://youtu.be/O8E3QBfjXO0

Here is a picture of the Arduino and motor control shield attached to the robo raptor:

Here is a picture taken from the video of it in demo mode:

After that picture was taken I managed to get it working on its batteries.

Here is the code for the demo.

Here is a link to the video on YouTube:

http://youtu.be/O8E3QBfjXO0

Here is a picture of the Arduino and motor control shield attached to the robo raptor:

Here is a picture taken from the video of it in demo mode:

After that picture was taken I managed to get it working on its batteries.

Here is the code for the demo.

// Robo-Raptor Demo

// demonstrates several actions the robo raptor can take.

// Written December 2013 by Bob Davis

#include AFMotor.h

#include Servo.h

// create servo object to control a servo

Servo myservo;

// mororr moves the right leg

// create motor #2, 64KHz pwm

AF_DCMotor motorr(2, MOTOR12_64KHZ);

// motorl moves the left leg

// create motor #4, 64KHz pwm

AF_DCMotor motorl(4, MOTOR12_64KHZ);

// motorw wiggles the tail, head moves too

// create motor #1, 64KHz pwm

AF_DCMotor motorw(1, MOTOR12_64KHZ);

// motorh moves the head up and down

// create motor #3, 64KHz pwm

AF_DCMotor motorh(3, MOTOR12_64KHZ);

char INBYTE;

// Set A6 as an output pin for speaker

int SpkrPin = 19;

int roar;

void setup() {

motorr.setSpeed(255); // set the speed to 255/255

motorl.setSpeed(255); // set

the speed to 255/255

motorw.setSpeed(255); // set

the speed to 255/255

motorh.setSpeed(255); // set

the speed to 255/255

pinMode(SpkrPin,

OUTPUT);

// The servo is on

pin 9

myservo.attach(9);

}

void loop() {

// Sequence of Motor

control commands:

// wait for tail

switch to get started

// wiggle tail back

and forth

// raise and lower

head three times

// take a few steps

walking forward

// make a roaring

sound

// Wait for tail

switch to start demo

while

(analogRead(A0) != '0'){}

// wiggle tail

motorw.run(BACKWARD); // wiggle

right

delay(200); // pause

motorw.run(RELEASE); //

stopped

delay(300);

motorw.run(FORWARD); // wiggle left

delay(200); // pause

motorw.run(RELEASE); //

stopped

delay(300);

motorw.run(BACKWARD); // wiggle

right

delay(200); // pause

motorw.run(RELEASE); //

stopped

delay(300);

motorw.run(FORWARD); // wiggle

left

delay(200); // pause

motorw.run(RELEASE); //

stopped

delay(300);

motorw.run(BACKWARD); // wiggle

right

delay(200); // pause

motorw.run(RELEASE); //

stopped

delay(300);

motorw.run(FORWARD); // wiggle

left

delay(200); // pause

motorw.run(RELEASE); //

stopped

delay(300);

// raise and lower

head

motorh.run(FORWARD); // raise

head

delay(300); // pause

motorh.run(BACKWARD); // lower

head

delay(300); // pause

motorh.run(RELEASE); //

stopped

delay(500);

motorh.run(FORWARD); // raise

head

delay(300); // pause

motorh.run(BACKWARD); // lower

head

delay(300); // pause

motorh.run(RELEASE); //

stopped

delay(500);

motorh.run(FORWARD); // raise

head

delay(300); // pause

motorh.run(BACKWARD); // lower

head

delay(300); // pause

motorh.run(RELEASE); //

stopped

delay(500);

// walk straight

forward

motorr.run(FORWARD); // right

foot forward

delay(300); // pause

motorr.run(BACKWARD); // right

foot backward

delay(300); // pause

motorr.run(RELEASE); // stop

right foot

delay(300); // pause

motorl.run(FORWARD); // left

foot forward

delay(300); // pause

motorl.run(BACKWARD); // left

foot backward

delay(300); // pause

motorl.run(RELEASE); // stop

left foot

delay(300); // pause

motorr.run(FORWARD); // right

foot forward

delay(300); // pause

motorr.run(BACKWARD); // right

foot backward

delay(300); // pause

motorr.run(RELEASE); // stop

right foot

delay(300); // pause

motorl.run(FORWARD); // left

foot forward

delay(300); // pause

motorl.run(BACKWARD); // left

foot backward

delay(300); // pause

motorl.run(RELEASE); // stop

left foot

delay(300); // pause

motorr.run(FORWARD); // right foot forward

delay(300); // pause

motorr.run(BACKWARD); // right

foot backward

delay(300); // pause

motorr.run(RELEASE); // stop

right foot

delay(300); // pause

motorl.run(FORWARD); // left

foot forward

delay(300); // pause

motorl.run(BACKWARD); // left

foot backward

delay(300); // pause

motorl.run(RELEASE); // stop

left foot

delay(300); // pause

//open mouth

myservo.write(0);

delay(300);

// roar

for (roar=200; roar

> 0; roar--) {

digitalWrite(SpkrPin, HIGH); //

sets the speaker on

delay(random(10)); // waits

for a fraction of a second

digitalWrite(SpkrPin, LOW); //

sets the speaker off

delay(random(10)); // waits

for a fraction of a second

}

//close mouth

myservo.write(90);

delay(300);

}

Toshiba L645 Disassembly and fan cleaning.

I recently had a Toshiba L645 come in for a power jack

replacement and a fan cleaning. The

power jack comes as a cable assembly that has to be ordered to fit the

laptop. There are some tricks to getting

it apart. There are screws in the

battery compartment holding the trim that covers the screws that holds in the

keyboard. There is a screw inside of the

memory compartment that holds the CD ROM drive in, and once it is removed there

is a screw located above where the drive was.

1 – Remove the 12 bottom screws.

2 – Remove the 2 screws for the hard drive drawer, and

remove hard drive.

3 – Remove the battery and remove 5 screws located below the

battery.

The two smaller screws hold the

keyboard bezel cover in place.

4 – Remove three keyboard bezel, the screws above the

keyboard, and the keyboard.

5 – Remove the seven screws under the keyboard, the right

two are shorter.

6 – Remove the 3 screws and the memory cover, inside there

is the CD ROM screw.

7 – Remove the CD-ROM drive and the screw hidden above it.

8 – Unscrew and/or unplug the wireless network card.

9 – Unplug the mouse, speakers and power switch, remove the

top cover of the laptop.

10 – Un-tape and unplug the video cable, and the USB/VGA

jack cable.

11 – Remove three motherboard screws marked with white

arrows, and one fan screw.

12 – Remove motherboard with the fan assembly.

13 – Remove 4 super tiny screws and remove the fan cover to

clean the fan.

As you can see in the picture the fan was fairly clogged

with dust. A small paint brush can

remove the dust. The picture quality is

not that great, I was using my cell phone camera.

When I reassembled it the screen did not work. The screen plug looked like it was plugged in

but it was not inserted properly. You

might want to mark the tape that holds it in with a marker prior to unplugging

it so you know if you have it back together correctly.

This picture shows the 5 screws that are located below the battery. Two of them hold the cover that gives access to the keyboard screws.

Wednesday, January 8, 2014

Three color RGB 8x8 LED Array

I recently obtained an 8 by 8 three color RGB LED array to play with. I set it up with three 74595 shift registers and an arduino. It was really easy to get it working. Here is a link to the company that sells the LED array.

http://www.icstation.com

Here is the video of it working on youtube:

http://youtu.be/wdONGo4giHs

I might eventually post the code but it follows my code that was used for the two color 8x8 arrays that is found in my book "Arduino LED Projects".

Here is a blue smiley face (with white hair) using the RGB array:

Here is a red, green, and blue flag using the RGB array:

I am contemplating making a larger RGB sign so I can do scrolling text in full color.

This is the schematic diagram:

http://www.icstation.com

Here is the video of it working on youtube:

http://youtu.be/wdONGo4giHs

I might eventually post the code but it follows my code that was used for the two color 8x8 arrays that is found in my book "Arduino LED Projects".

Here is a blue smiley face (with white hair) using the RGB array:

Here is a red, green, and blue flag using the RGB array:

I am contemplating making a larger RGB sign so I can do scrolling text in full color.

This is the schematic diagram:

Wednesday, November 6, 2013

Remote selection relay design

We recently had an application where we needed to remotely switch

between two RF amplifiers. I used Google and searched to find a solution to no avail. So I am posting this to save the next person a lot of time.

All we had available was the single transmission line coming from the RF amplifier. We were sending DC up the transmission line to power the amplifier. Because of a lightning issue we could not use anything “solid state” to create a working solution. The first thing that comes to mind is reversing the 12 VDC to switch amplifiers, but then the amplifiers negative input was fastened to ground so that cannot be done.

However there are some solutions to switching between the two amplifiers by pulsing the power to the remote amplifier. All we can do is interrupt the power for a fraction of a second to switch between the amplifiers.

All we had available was the single transmission line coming from the RF amplifier. We were sending DC up the transmission line to power the amplifier. Because of a lightning issue we could not use anything “solid state” to create a working solution. The first thing that comes to mind is reversing the 12 VDC to switch amplifiers, but then the amplifiers negative input was fastened to ground so that cannot be done.

However there are some solutions to switching between the two amplifiers by pulsing the power to the remote amplifier. All we can do is interrupt the power for a fraction of a second to switch between the amplifiers.

One solution is to use an “alternating” “impulse” or

“bistable” relay. The most common such

relay is the S89R11DAC1-12. It is available from all major vendors. The biggest problem with that relay is that

it draws half an amp of power. That

might be solved by putting a capacitor between the power source and the relay

so that the relay is only activated for a few seconds when the power is turned

on or when it is turned off then back on.

It is also a rather large relay and it is not socketed for easy

replacement. Here is a picture of what

that relay looks like.

Solution number two is to use what is called a magnetic

latching relay. These relays have two

coils, one to turn it on and one to turn it off. A capacitor in series with the relay creates

a pulse that either turns the relay on or turns the relay off depending on what

coil is selected. There are several

kinds of these magnetic latching relays that are available. Model number 755XBXCD-12D has a round base

and 785XBXCD-12D has a square base. Here

is a possible, untested, schematic.

The next solution is to use a conventional relay but use a capacitor to detect how long the power was off. If the power has been off for a long time then the capacitor will be discharged. When power comes back on the capacitor is a “short” thus delivering 12 volts to the relay. If the power was only off for less than a second, then the capacitor is still charged and the relay only gets about three volts. That is not enough voltage to turn the relay on. The 12 volt relay I tested had a 150 ohm coil and required 9 volts to turn on, but it will stay on all the way down to three volts. Hence the relay will be turned on or off depending on how long the power was off. Here is the schematic; it was tested to work with a power supply of 9 volts all the way up to 16 volts:

Friday, November 1, 2013

A brief history of health insurance - why obamacare is a failure

A brief history of health insurance – or why some of us knew

that obamacare would be a flop.

**This is my personal opinion and is full of sarcasm, it is not meant to be entirely accurate**

**This is my personal opinion and is full of sarcasm, it is not meant to be entirely accurate**

Many years ago, most people did not have insurance. However, back then there were lots of “nonprofit”

hospitals that would gladly take anyone without insurance. When my first two children were born we paid

the hospital $100 a month for 10 months to cover all of the expenses. The money went directly to the hospital or

doctors, there were no middlemen.

Eventually those “nonprofit” hospitals were bought out and bulldozed. Hospitals are now in the business of making

money.

Then after that change, there was what is called “Major

medical” insurance. It cost our employer

about $1000 a year and it covered everything medical that totaled over $2000. We kept all of the paperwork ourselves and then

submitted it at the end of the year. Our

insurance company then sent us a check for everything that totaled over

$2000. We then used that money to cover

the medical expenses for the next year.

Then disaster struck.

Our wonderful government thought that it would fix the “problems” with health

insurance. They passed laws that invented

what is called an “HMO”. HMO insurance

included “Free” physicals and many other “free” things because, as we all well know,

if you see the doctor for free you will not get sick and hence you will save a

lot of money. HMO’s also required that

the primary care doctor would do all of the paperwork so he had to hire two or

three secretaries just to process all of that paperwork. HMO’s would save money because the doctor

would detect problems earlier and you would not get as sick. OK, maybe the premiums would go up a little because

someone had to pay for all of the secretaries to process the paperwork and

someone had to pay for all of those “free” physicals, etc. Insurance went from $1000 a year to $10,000 a

year. Thanks to the US government for figuring

out how to save us money. As a result

many people were no longer insured.

Then along comes more help from the “experts” on saving

money. Yes ObamaScare to the rescue! His idea was that if those who were well paid

a little [lot] more they could cover the expenses of those who were sick. He also eliminated being refused insurance because

of “preexisting” conditions. He also

included coverage for a lot of things like abortions and sex changes. Of course someone has to pay for all of those

new extra benefits. On top of that, if

you had insurance that did not include all of the new extra benefits, it has to

be cancelled. So as a result about 1/2

to 3/4 of those with insurance will find that their insurance is now cancelled. However they will not be able to afford the

increased premiums, to pay for those that are already sick, so in the end as

much as 1/2 or more of the population will be left without any health

insurance.

On top of that there is the now delayed “Employer Mandate”. Any company with more than a few employees is

required to give “free” health care insurance to all of its full time

employees. The solution is simple, make

them “part time” employees. This led to

massive job reductions and that led the “Employer Mandate” being delayed until

after the election.

Now if we were to go back to directly paying the doctors we could cut the cost in half because all middle men (insurance companies) do is increase the cost of seeing your doctor. Remember ObamaScare is not medical coverage, it is health insurance, there is a huge difference there.

Common Radio Frequency Questions - RF FAQ

Radio Frequency FAQ’s

I now work for a company called ComProd Communications. You can find us at www.comprodcom.com We specialize in Creating RF Solutions. There are several questions that we get asked

a lot. Here are some of the most common

questions.

My antenna came with a ground plane; do I need to use it?

The ground plane is a critical part of any antenna system. It has both a minimum size as in length and

width, as well as a specific distance that it has to be from the antenna. If you have to replace it for some reason the

replacement but be larger in size as far as length and width, and it must be

the exact same distance from the antenna!

The distance is critical because the reflected signal has to be in phase

with the signal emitted from the antenna.

Changing the distance will cause canceling of the output of the

antenna. Making it smaller will affect

the impedance of the antenna as the amount of reflected signal will vary over

the length of the antenna.

Why has the cost of Combiners gone up while the cost of

transmitters and receivers has gone down?

As transmitters and receivers have gotten cheaper their

sensitivity and selectivity has gone down.

If the combiner does not remove unwanted frequencies then the receivers

will be overloaded in their front end.

Let’s say we have a transistor RF amplifier running on 12 volts. If it has an input signal that produces an

output that is over 12 volts peak to peak it will turn it into a square wave

and produce tons of harmonics. This will

totally hide the frequency that you want to receive. The combiner must remove the unwanted

frequency from both the transmitter and the receiver in order for the receiver

to work correctly.

Are antennas best stacked vertically or horizontally?

Back in the early days of audio it was common to see lots of

speakers positioned horizontally across the front of the stage. The concept was to have a speaker aimed at

everyone in the audience. At some point

engineers started pointing out that if you stack the speakers one on top of the

other (Vertically) you get much better sound dispersion. Although this does not look correct to the

eyes, time and experience has proven that it works. Now most bands use vertically stacked

speakers. The same is true with

antennas. Mounting antennas one above

the other seems like it would be sending signals out into space, but instead it

concentrates the beam horizontally.

Why do we need separate receive and transmit antennas?

Transmitters emit some signals at unwanted frequencies,

usually close to their primary broadcast frequency. These unwanted frequencies are rapidly reduced

in strength as you move away from the transmitting antenna. However these unwanted signals can easily

interfere with receivers that are operating on nearby frequencies. If you have a separate transmit and receive

antenna this problem can be drastically reduced. Otherwise the frequency of the receiver needs

to be removed from the transmitters output as well as the frequency of the

transmitter must be removed from the receivers input. Tuesday, October 29, 2013

Replacing the stove vent hood

Replacing the stove vent hood should be an easy thing to do. However I wanted it to vent inside in the winter and then vent outside in the summer. I also had to adapt from the new exhaust size of 7 inches to the old pipe size of 5 inches. I used a 7 inch to 6 inch adapter, then a 6 inch to 5 inch adapter. Then to shut off the external vent during the winter I added a 6 inch flapper. I had to cut off the old 5 inch pipe to make room for the new adapters. Then I had to cut 1 inch slots in the old 5 inch pipe to get the new adapter to fit inside of it.

I also had to cut bigger holes in the cupboard to fit the new 7 inch diameter pipe adapter. Then I had to cut it two more times to make room for everything to fit together.

Then I had to assemble the adapters with the closer/flapper and test it all out prior to installation.

This is what it looked like once assembled in the cupboard. The hole in the top of the cupboard is now closed off with duct tape. Cutting a piece of thin plywood to fit using a cardboard model would have looked better.

I forgot a picture of what it all looks like once assembled, hopefully I will include that soon.

I also had to cut bigger holes in the cupboard to fit the new 7 inch diameter pipe adapter. Then I had to cut it two more times to make room for everything to fit together.

Then I had to assemble the adapters with the closer/flapper and test it all out prior to installation.

This is what it looked like once assembled in the cupboard. The hole in the top of the cupboard is now closed off with duct tape. Cutting a piece of thin plywood to fit using a cardboard model would have looked better.

I forgot a picture of what it all looks like once assembled, hopefully I will include that soon.

Dodge Stratus Fan speed control

My wife's Dodge Stratus developed a second heat control problem. The heater fan only worked on high. This has happened to me before on other vehicles but I could not locate the speed control assembly. Someone told me to check under the passengers side dash near the blower motor. It is almost impossible to see it there, without a mirror, but I was able to get a picture of it. First remove the flimsy nut that holds on the cover, then remove the cover, and then it is visible. Remove the two mounting screws and turn it around so you can see the back side to disconnect the electrical wires. It requires releasing two catches to be disconnected.

The fan speed control is the light gray thing on the lower right side of this picture.

The fan speed control is the light gray thing on the lower right side of this picture.

Subscribe to:

Posts (Atom)

.jpg)