// Sunrise 7x96 Uno LED Array driver

// Easier to read code

// 4/4/2024 by Bob Davis

#define Data 7// Data pin

#define CLK 8 // Port B assignments

#define OE 9 // 74138 pins 4 and 5

#define LAT 10// Latch

#define A0 11 // 74138 pin1

#define A1 12 // 74138 pin2

#define A2 13 // 74138 pin3

String text="ARDUINO+SUNRISE ";

// This font from http://sunge.awardspace.com/glcd-sd/node4.html

byte font[][7] = {

0x00,0x00,0x00,0x00,0x00,0x00,0x00, // ascii 32

0x00,0x00,0xfa,0x00,0x00,0x00,0x00, // !

0x00,0xe0,0x00,0xe0,0x00,0x00,0x00, // "

0x28,0xfe,0x28,0xfe,0x28,0x00,0x00, // #

0x00,0x34,0xfe,0x58,0x00,0x00,0x00, // $

0xc4,0xc8,0x10,0x26,0x46,0x00,0x00, // %

0x6c,0x92,0xaa,0x44,0x0a,0x00,0x00, // &

0x00,0xa0,0xc0,0x00,0x00,0x00,0x00, // '

0x00,0x38,0x44,0x82,0x00,0x00,0x00, // (

0x00,0x82,0x44,0x38,0x00,0x00,0x00, // )

0x10,0x54,0x38,0x54,0x10,0x00,0x00, // *

0x10,0x10,0x7c,0x10,0x10,0x00,0x00, // +

0x00,0x0a,0x0c,0x00,0x00,0x00,0x00, // ,

0x10,0x10,0x10,0x10,0x10,0x00,0x00, // -

0x00,0x06,0x06,0x00,0x00,0x00,0x00, // .

0x04,0x08,0x10,0x20,0x40,0x00,0x00, // /

0x7c,0x8a,0x92,0xa2,0x7c,0x00,0x00, // 0

0x00,0x42,0xfe,0x02,0x00,0x00,0x00, // 1

0x42,0x86,0x8a,0x92,0x62,0x00,0x00, // 2

0x84,0x82,0xa2,0xd2,0x8c,0x00,0x00, // 3

0x18,0x28,0x48,0xfe,0x08,0x00,0x00, // 4

0xe4,0xa2,0xa2,0xa2,0x9c,0x00,0x00, // 5

0x3c,0x52,0x92,0x92,0x0c,0x00,0x00, // 6

0x80,0x8e,0x90,0xa0,0xc0,0x00,0x00, // 7

0x6c,0x92,0x92,0x92,0x6c,0x00,0x00, // 8

0x60,0x92,0x92,0x94,0x78,0x00,0x00, // 9

0x00,0x6c,0x6c,0x00,0x00,0x00,0x00, // :

0x00,0x6a,0x6c,0x00,0x00,0x00,0x00, // ;

0x00,0x10,0x28,0x44,0x82,0x00,0x00, // <

0x28,0x28,0x28,0x28,0x28,0x00,0x00, // =

0x82,0x44,0x28,0x10,0x00,0x00,0x00, // >

0x40,0x80,0x8a,0x90,0x60,0x00,0x00, // ?

0x4c,0x92,0x9e,0x82,0x7c,0x00,0x00, // @

0x7e,0x90,0x90,0x90,0x7e,0x00,0x00, // A

0xfe,0x92,0x92,0x92,0x6c,0x00,0x00, // B

0x7c,0x82,0x82,0x82,0x44,0x00,0x00, // C

0xfe,0x82,0x82,0x82,0x7c,0x00,0x00, // D

0xfe,0x92,0x92,0x92,0x82,0x00,0x00, // E

0xfe,0x90,0x90,0x80,0x80,0x00,0x00, // F

0x7c,0x82,0x82,0x8a,0x4c,0x00,0x00, // G

0xfe,0x10,0x10,0x10,0xfe,0x00,0x00, // H

0x00,0x82,0xfe,0x82,0x00,0x00,0x00, // I

0x04,0x02,0x82,0xfc,0x80,0x00,0x00, // J

0xfe,0x10,0x28,0x44,0x82,0x00,0x00, // K

0xfe,0x02,0x02,0x02,0x02,0x00,0x00, // L

0xfe,0x40,0x20,0x40,0xfe,0x00,0x00, // M

0xfe,0x20,0x10,0x08,0xfe,0x00,0x00, // N

0x7c,0x82,0x82,0x82,0x7c,0x00,0x00, // O

0xfe,0x90,0x90,0x90,0x60,0x00,0x00, // P

0x7c,0x82,0x8a,0x84,0x7a,0x00,0x00, // Q

0xfe,0x90,0x98,0x94,0x62,0x00,0x00, // R

0x62,0x92,0x92,0x92,0x8c,0x00,0x00, // S

0x80,0x80,0xfe,0x80,0x80,0x00,0x00, // T

0xfc,0x02,0x02,0x02,0xfc,0x00,0x00, // U

0xf8,0x04,0x02,0x04,0xf8,0x00,0x00, // V

0xfe,0x04,0x18,0x04,0xfe,0x00,0x00, // W

0xc6,0x28,0x10,0x28,0xc6,0x00,0x00, // X

0xc0,0x20,0x1e,0x20,0xc0,0x00,0x00, // Y

0x86,0x8a,0x92,0xa2,0xc2,0x00,0x00, // Z

};

void setup() {

Serial.begin(9600);

Serial.println("Arduino is ready");

pinMode (Data, OUTPUT); // Data pin to output

pinMode (CLK, OUTPUT); // Clock pin to output

pinMode (OE, OUTPUT); // Out Enable pin to output

pinMode (LAT, OUTPUT); // Latch pin to output

pinMode (A0, OUTPUT); // Address pin to output

pinMode (A1, OUTPUT); // Address pin to output

pinMode (A2, OUTPUT); // Address pin to output

}

void loop() {

if (Serial.available() > 0){

text=Serial.readString();

text.toUpperCase();

Serial.print(text);

}

// Select the Row

for (int r=0; r<8; r++){

// select the character

for (int ch=17; ch>-1; ch--){

// select the column within character

for (int c=5; c>-1; c--){

digitalWrite(Data, HIGH); // Data is inverted!

if ((font[text[ch]-32][c] >> r+1) & 0x01==1) digitalWrite(Data, LOW);

digitalWrite(CLK, LOW); // Toggle Clock

digitalWrite(CLK, HIGH);

}

}

// This row is done so display it

digitalWrite(OE, HIGH); // Turn off display

digitalWrite(LAT, HIGH); // Latch data

digitalWrite(LAT, LOW); // Ready for next latch

digitalWrite(A0, LOW); // Update Row

digitalWrite(A1, LOW);

digitalWrite(A2, LOW);

if ((r & 0X01)==1) digitalWrite(A0, HIGH);

if ((r & 0X02)==2) digitalWrite(A1, HIGH);

if (r > 3) digitalWrite(A2, HIGH);

digitalWrite(OE, LOW); // Display back on

}

}

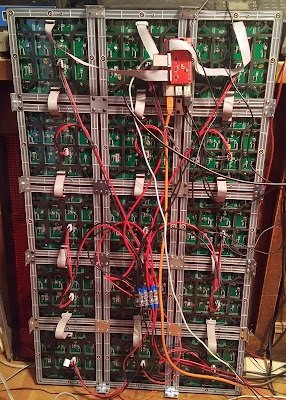

Here is a picture of the wiring from the back side.