I have added the ability to select the background color to my LED sign software. The format is 080100 TEXT. The numbers are for RGB foreground colors and RGB background colors. Our cat Momo photobombed one of my video shoots.

Here is the video:

This is a picture of the controller. The Bluetooth module is plugged directly into D0 and D1 at the top. The network jack has eight 330 ohm resistors in series. Power comes in on the Vin and ground pins.

The strips come in rolls of five meters or 16.4 feet and need to be cut into 4 or 5 foot lengths depending on the size of the sign.

Here I am adding the strips to a sign board background.

This is the back side of the sign. Power comes into all 16 LED strips but the lower eight have their data from the other side of the top eight strips. There are two power connectors for five volts at 15 amps each. You can connect them together to a 5 volt 30 amp power supply.

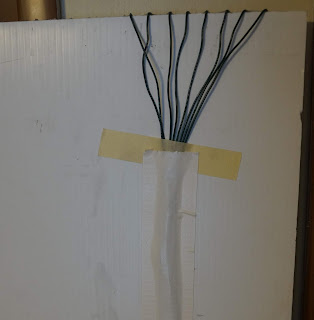

This is the eight data wrap around lines from the top eight strips going to the lower eight strips.

Here are two pictures of one of my signs in a store window.

Here is another Video showing some new features.